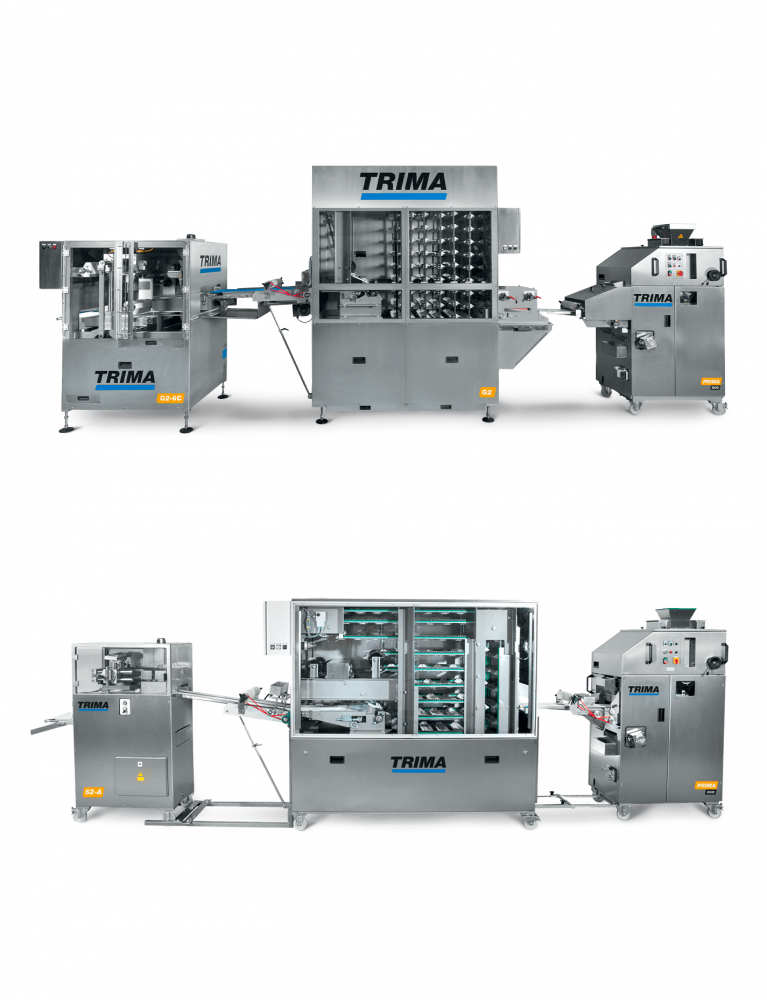

G2-6C/6SL

The G2-6C and G2-6SL models enhance the Compact Line’s performance to create a complete modular line that can be easily operated by just one person. The main difference between the two is in the variety of products. For example, G2-6C is perfect for round buns and patterned rolls, whereas G2-6SL can make a broader range of products (in terms of weight and shape) because of its moulding station.

Type of Bun

G2 6C

- Modular pre-proofing cabinet with a proofer, a pre-rolling unit, and a stamping station

- Perfect for making round buns and long rolls

- With integrated round stamping cups and interchangeable tools

- Rotating stamping tool for Kaiser rolls and pressing tool for all other buns and rolls

- 6-minute proofing time with 150 swing trays and a capacity of approximately 3000 pcs/hour

- Swing tray for max. 150 g dough pieces

- Removable trays all along the system (lower part)

- Tray for manual product removal

G2 6SL

- Modular pre-proofing cabinet with a proofer, a long-roll moulder, and a stamping station

- Moulding station with height-adjustable pressure board and adjustable double calibration rollers

- Stamping station with integrated round stamping cups and interchangeable tools

- Interchangeable stamping tool for original Kaiser rolls and other products

- 6-minute proofing time with 150 swing trays and a capacity of approximately 3000 pcs/hour

- Swing tray for max. 150 g dough pieces

- Tray for manual product removal

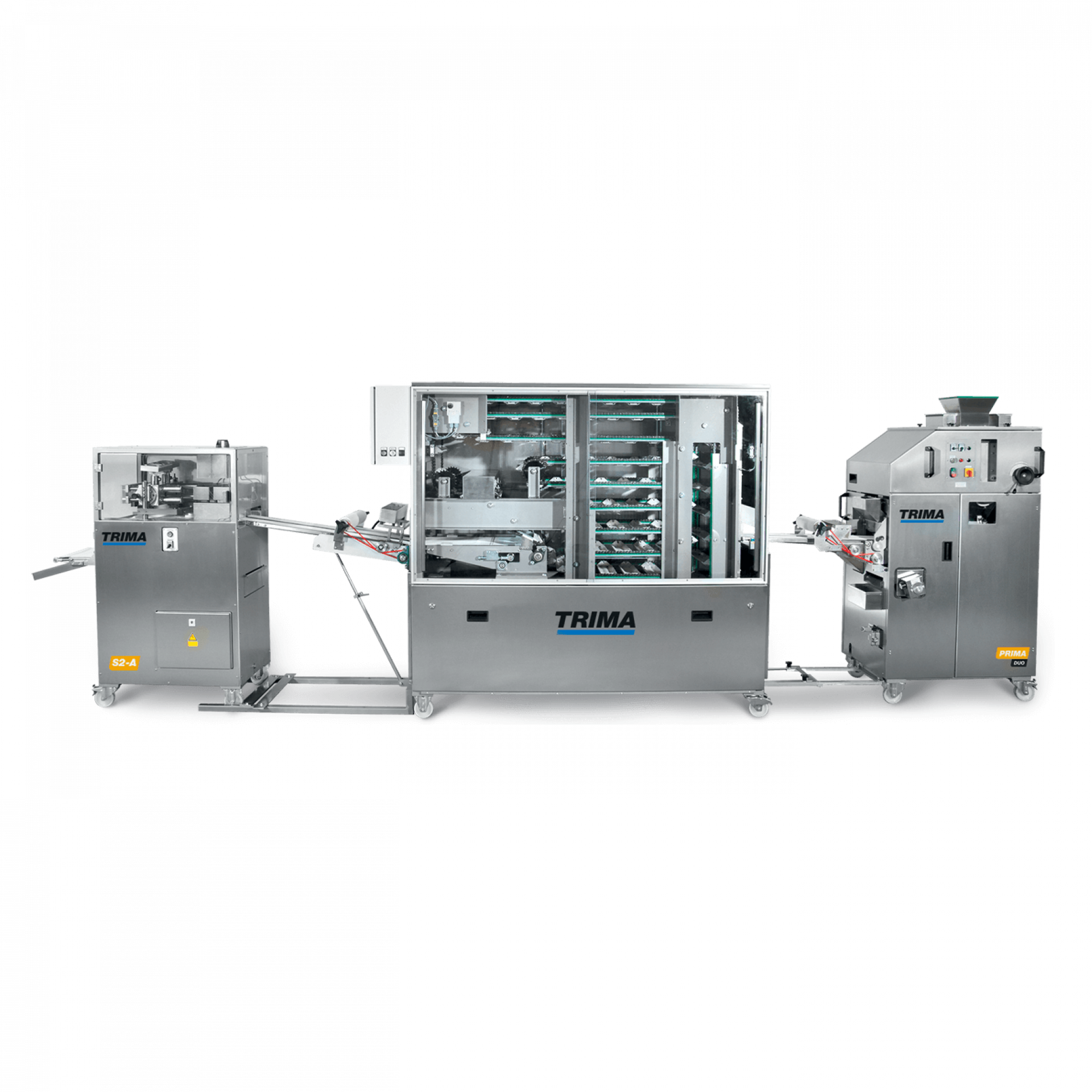

At the beginning of each line stands Prima Duo

3200 pieces

This is the maximum capacity per hour of the 2-row version with only one person operating it.

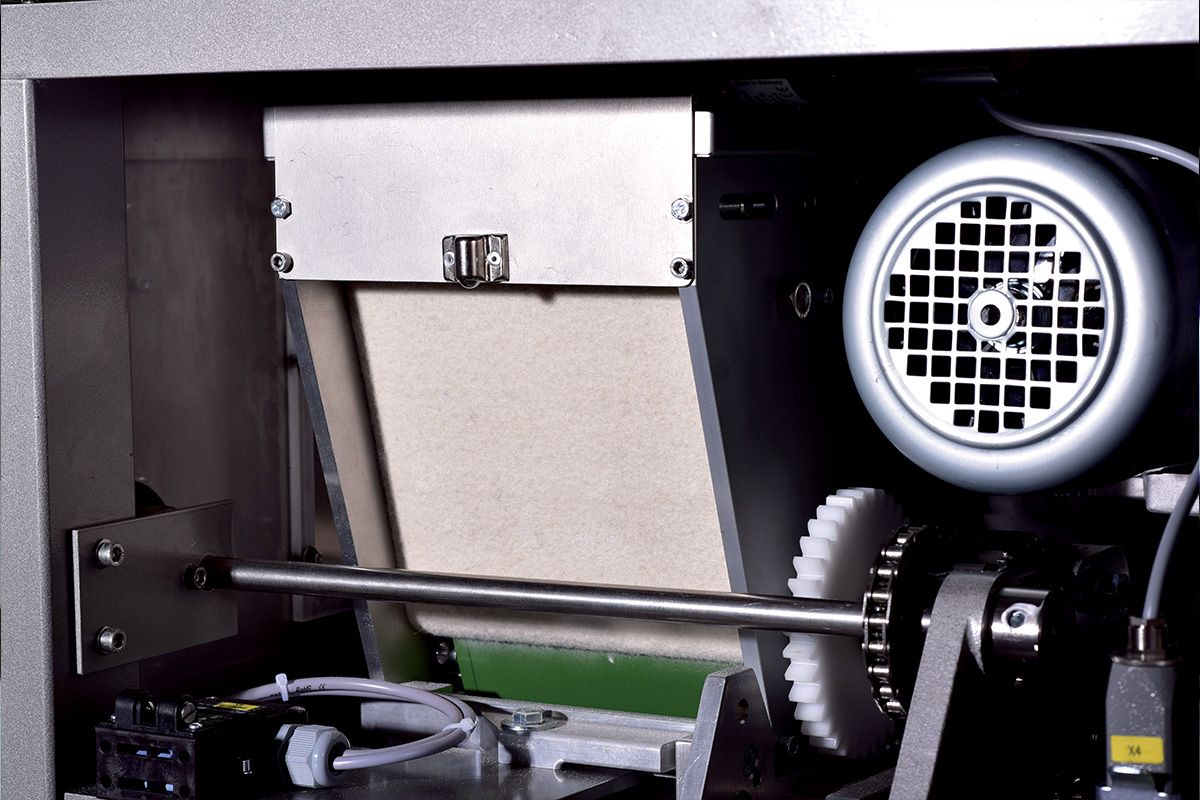

Infeed belts

These belts gently convey the dough to the chamber without stressing it, so less flour is needed.

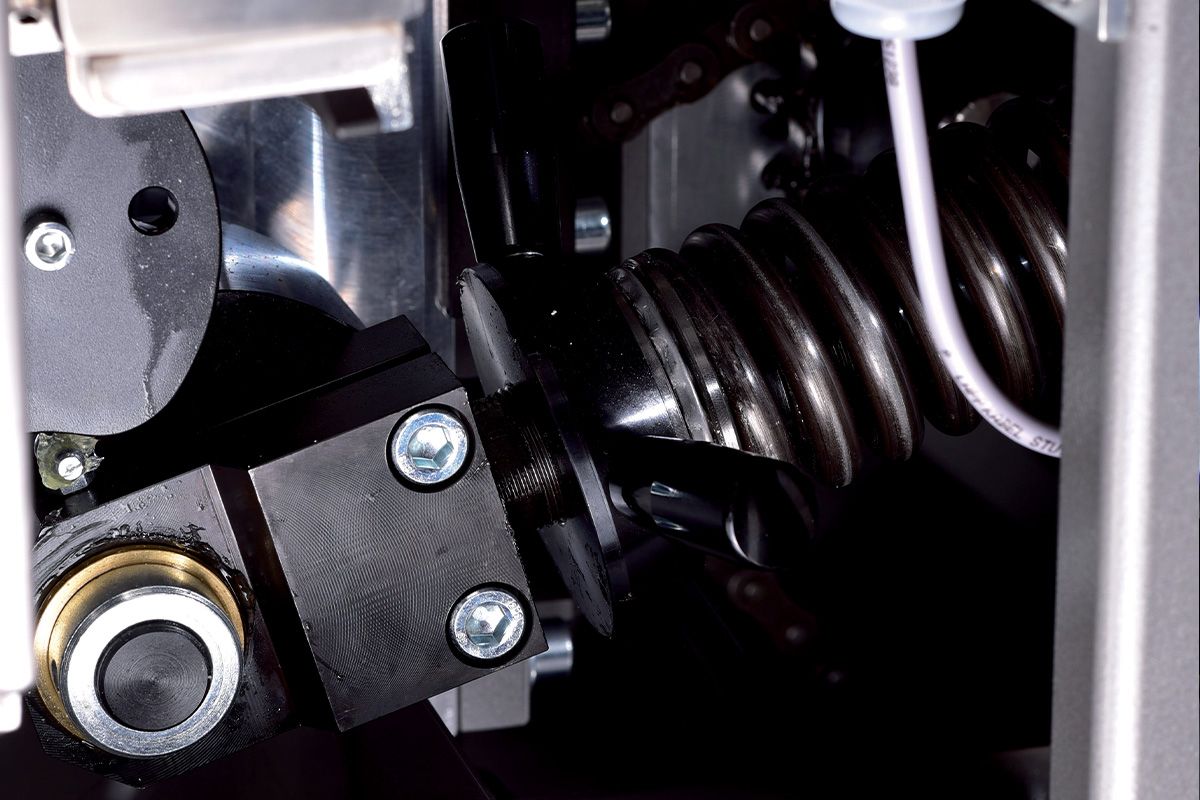

Adjustable pressure

You can adjust the pressure on the dough based on its texture. This innovative system doesn’t stress the dough, ensuring optimal processing.

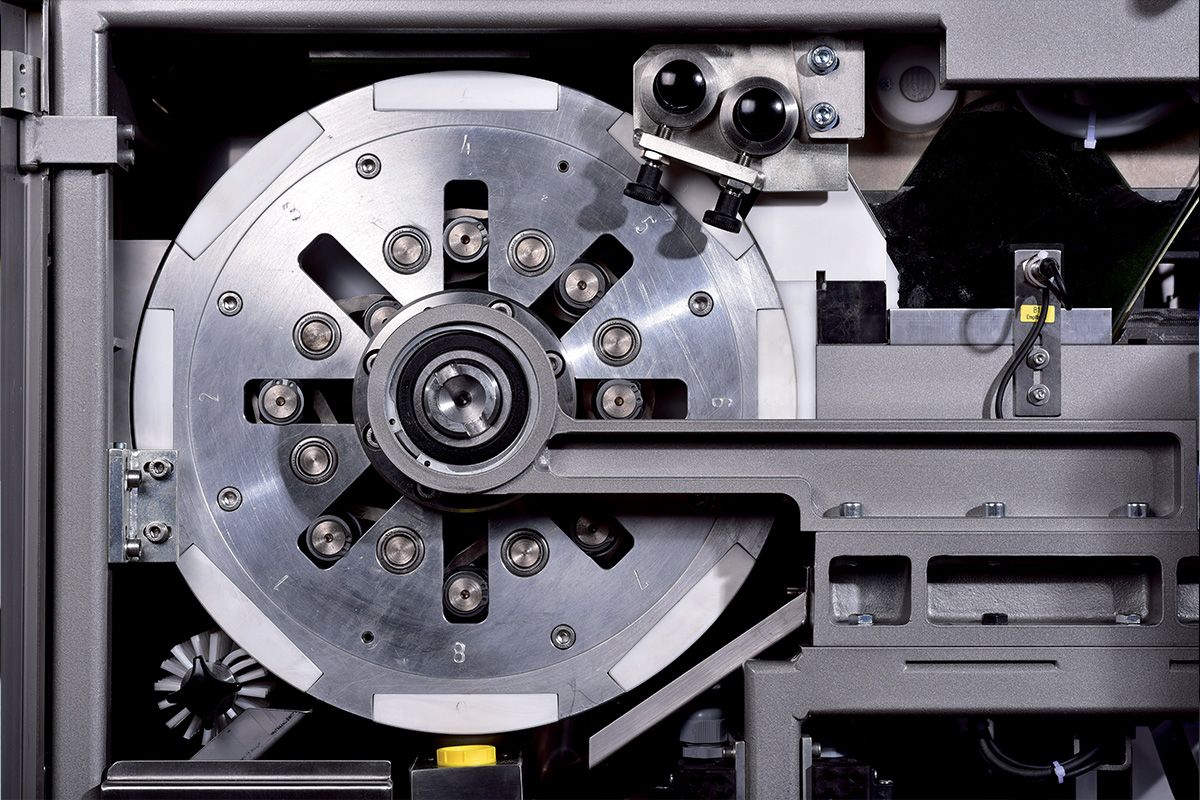

Double-piston drum

It allows you to make a wide variety of buns of varying weight without having to replace any mechanical components, thus saving you time and money.

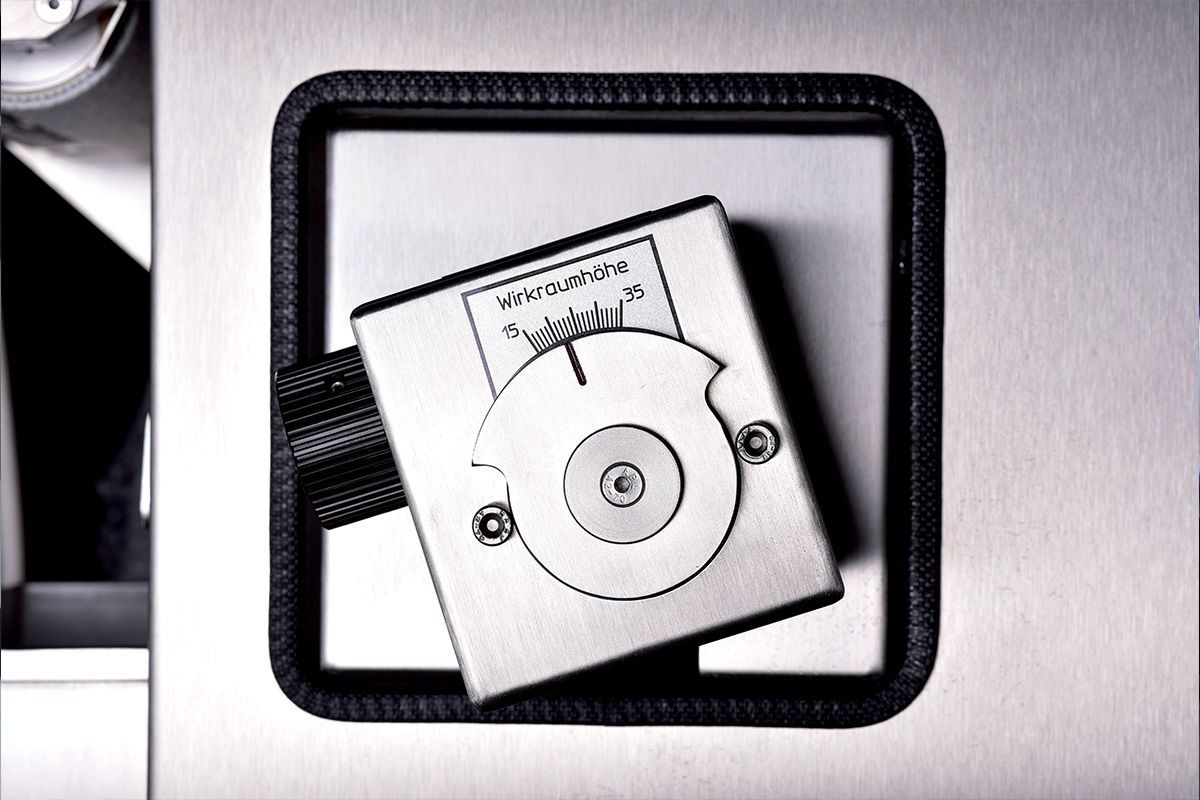

Separate rounding chamber adjustment

You can adjust the rounding space regardless of the dough piece’s weight. This option reduces the pressure on the dough, processing it without stressing it or compromising its volume.

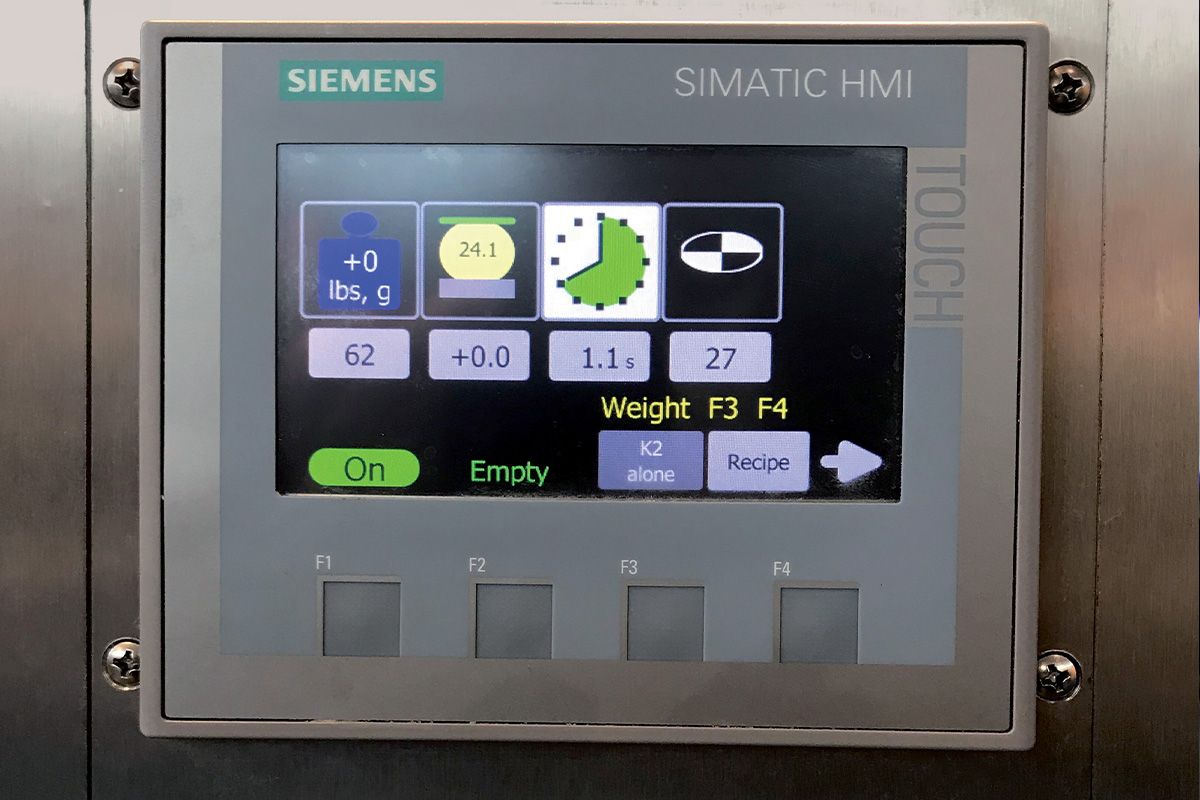

Interactive touch screen

Available in the Future version. It allows you to set all the machine parameters (e.g., weight, rounding chamber, rounding speed and time, flour duster).

You can even save all these settings as a recipe for future use.

This is the maximum capacity per hour of the 2-row version with only one person operating it.

These belts gently convey the dough to the chamber without stressing it, so less flour is needed.

You can adjust the pressure on the dough based on its texture.

This innovative system doesn’t stress the dough, ensuring optimal processing.

It allows you to make a wide variety of buns of varying weight without having to replace any mechanical components, thus saving you time and money.

You can adjust the rounding space regardless of the dough piece’s weight. This option reduces the pressure on the dough, processing it without stressing it or compromising its volume.

Available in the Future version. It allows you to set all the machine parameters (e.g., weight, rounding chamber, rounding speed and time, flour duster).

You can even save all these settings as a recipe for future use.

Find out more about using the machine as part of a compact line, for the production of a wide variety of bread rolls.

Dividers & Rounders

Our dough divider-rounders are like no other because they process dough as gently and carefully as an artisan baker, ensuring excellent precision and high output. Prima Duo, Prima Trio, and Prima Evo meet the needs of all bakeries, from small artisan to large industrial ones.

Prima Duo

Prima Trio

Prima Evo