Prima Evo: 4, 5, 6-row dough divider-rounder

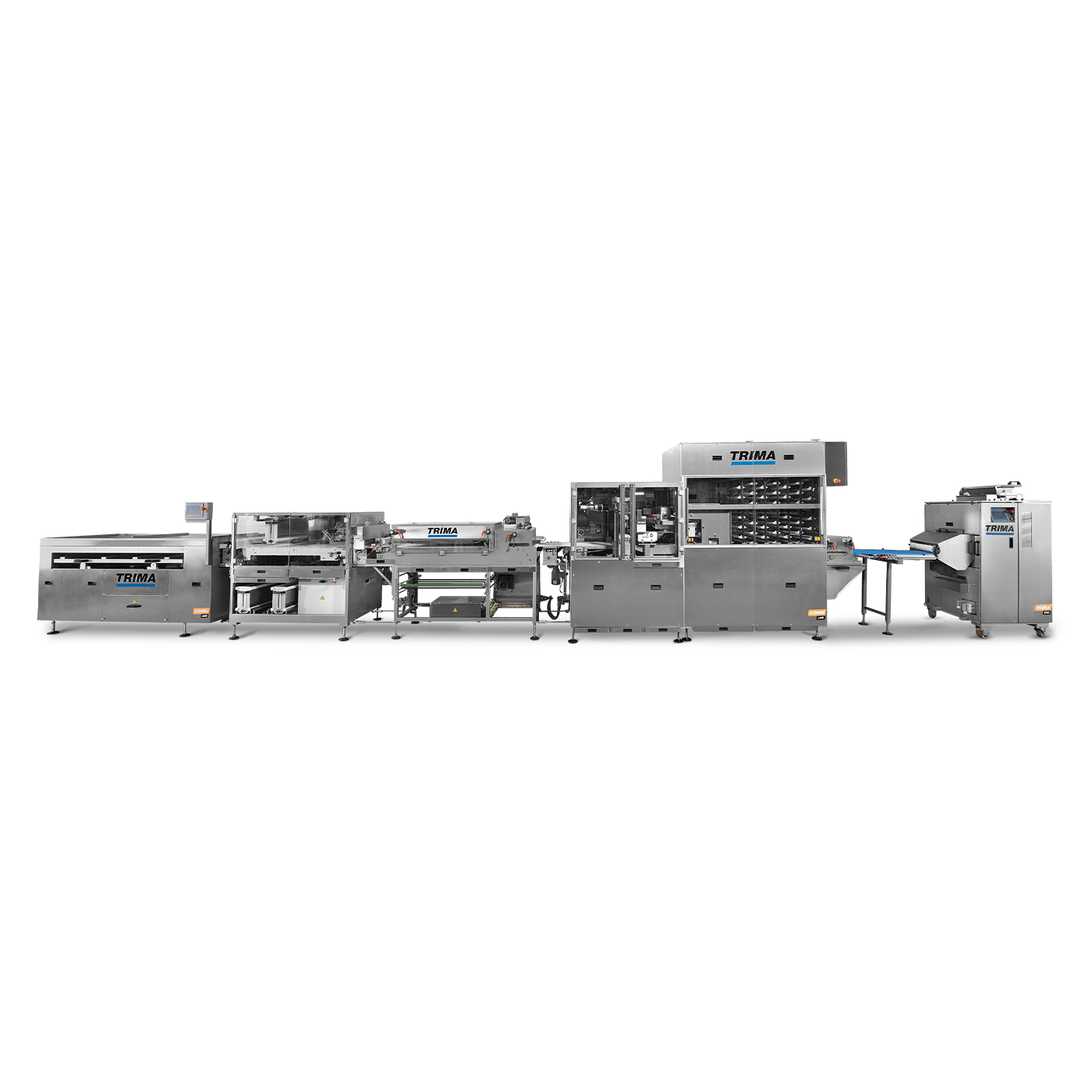

Prima Evo is the best choice for maximum efficiency and results of the highest quality. With a capacity of up to 9000 identical dough pieces per hour, it’s the ideal solution for medium to large-sized businesses. Its internal mechanism, designed and manufactured by Trima, perfectly mimics the hands of a master baker. The Classic version is operated through mechanical controls and the Future version through a touchscreen. Both versions allow you to set all the parameters to process the dough without stressing it, whatever the size or weight of the pieces you want to obtain. Prima Evo can be used as a standalone machine or integrated as a head machine into a CombiLine, Multi Line, or Panning Line.

Weight Range

20 – 70 g

30 – 85 g

35 – 90 g

40 – 100 g

45 – 110 g

50 – 120 g

60 – 140 g

70 – 160 g

75 – 170 g

Capacity

max 9000 pcs/hour with the 6-row version

max 7500 pcs/hour with the 5-row version

max 6000 pcs/hour with the 4-row version

Master bakers’ expertise is the inspiration behind this innovative dough divider-rounder that gently processes dough, ensuring great weight accuracy.

Plus

9000 pieces

This is the maximum capacity per hour of the 6-row version (stepless adjustment available). Up to 7500 pcs/hour with the 5-row version and 6000 pcs/hour with the 4-row version.

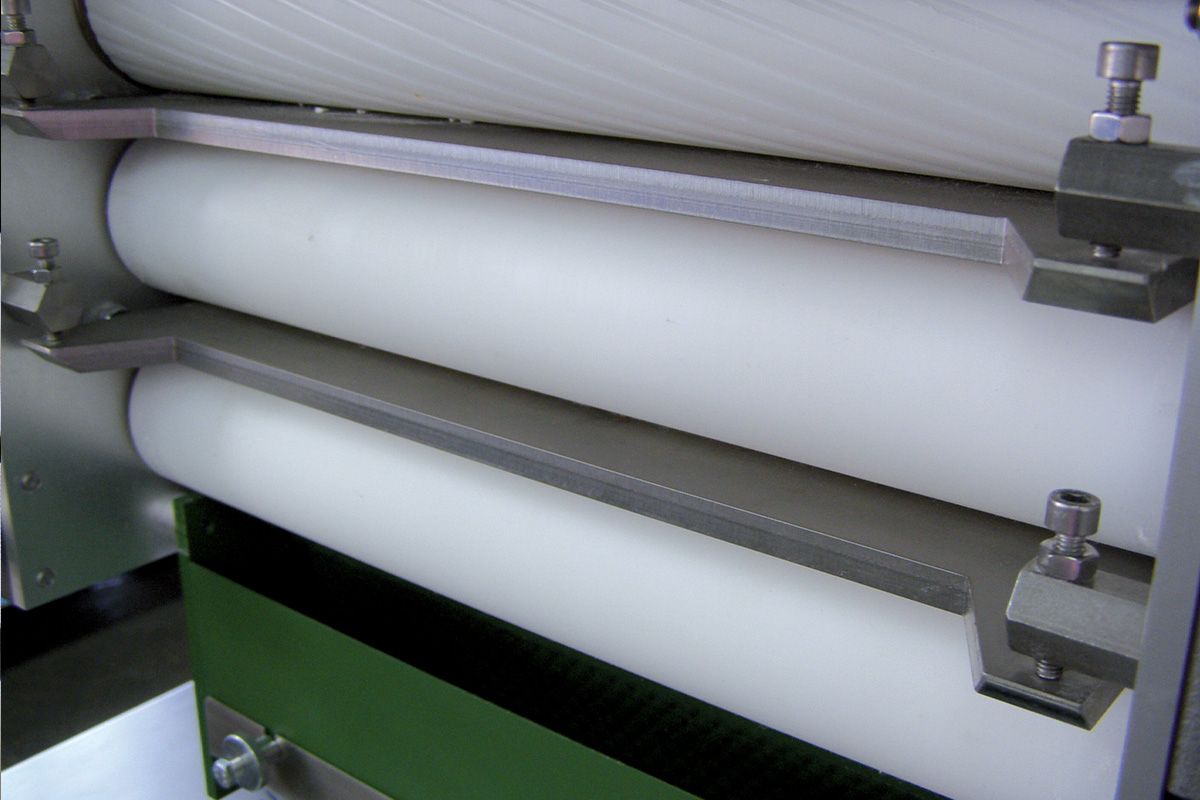

Infeed rollers

These rollers gently convey the dough to the chamber without stressing it, so less flour is needed.

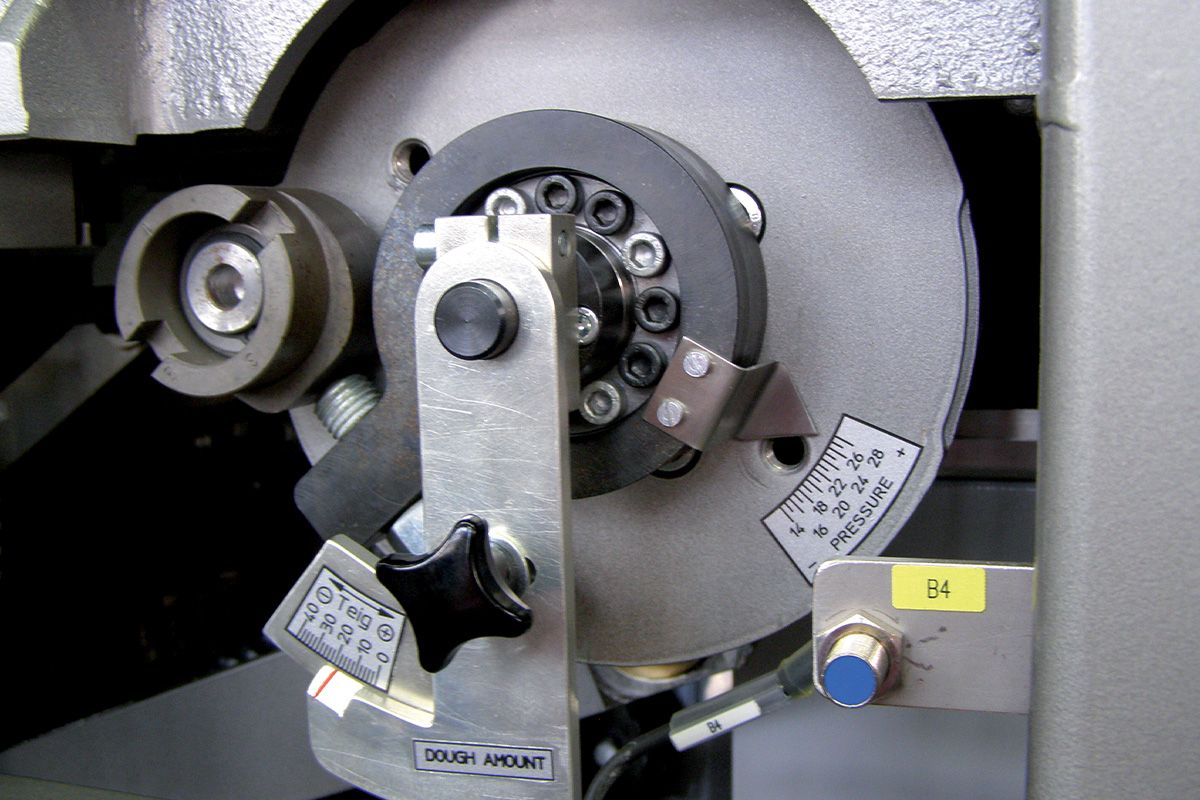

Adjustable pressure

You can adjust the pressure and amount of dough based on its texture. This innovative system doesn’t stress the dough, ensuring optimal processing.

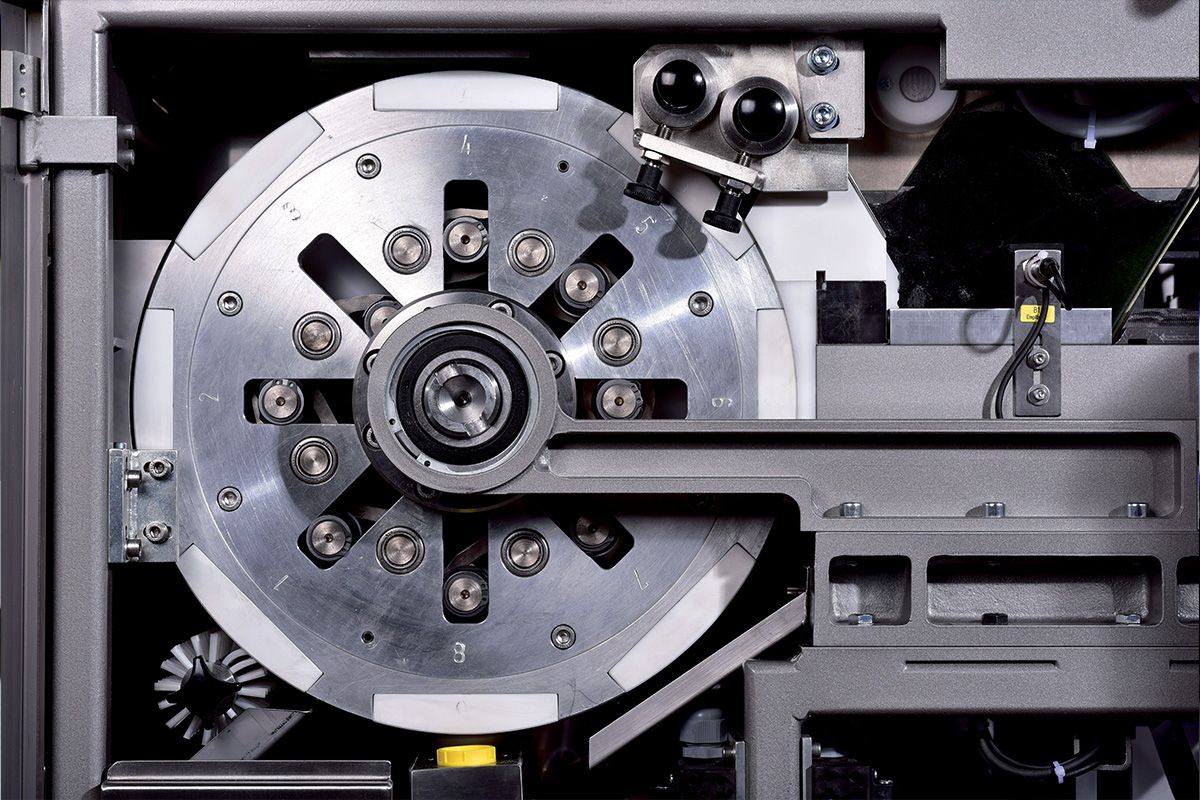

Double-piston drum

It allows you to make a wide variety of buns of varying weight without having to replace any mechanical components, thus saving you time and money.

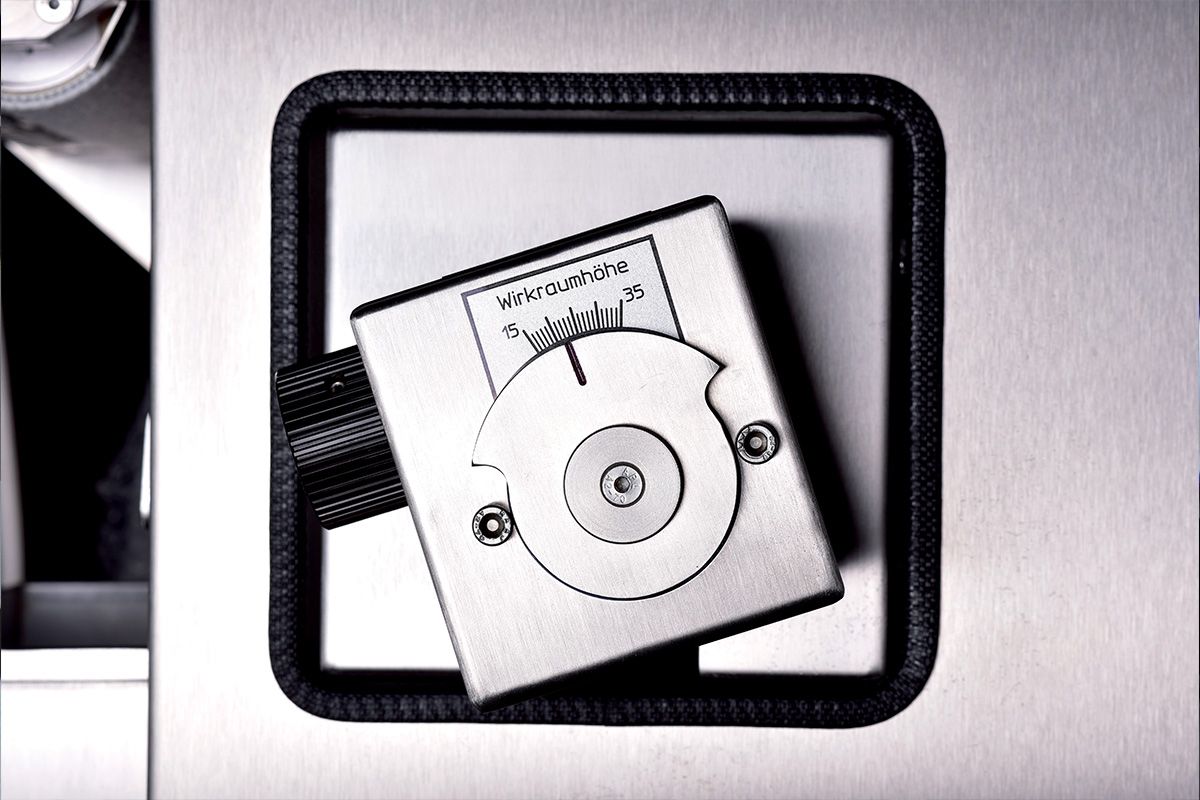

Separate rounding chamber adjustment

You can adjust the rounding space regardless of the dough piece’s weight. This option reduces the pressure on the dough, processing it without stressing it or compromising its volume.

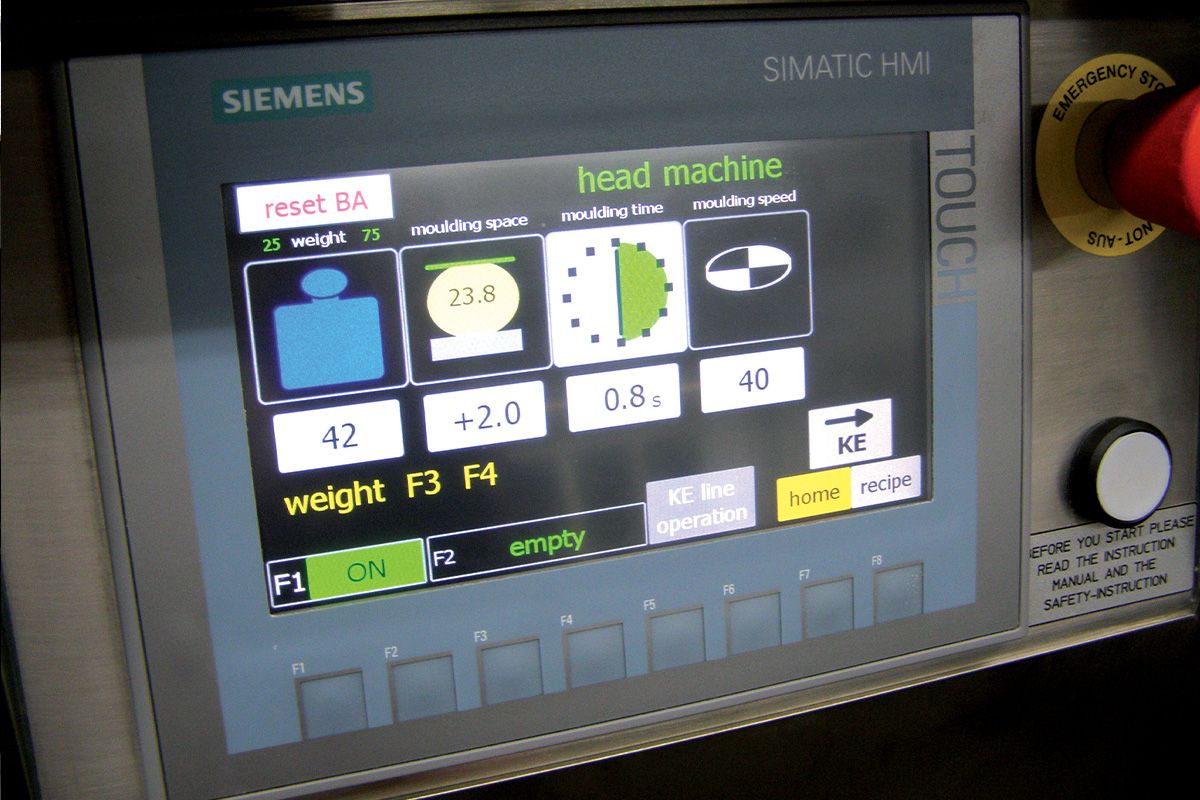

Interactive touch screen

Available in the Future version. It allows you to set all the machine parameters (e.g., weight, rounding chamber, rounding speed and time, flour duster).

You can even save all these settings as a recipe for future use.

Easy to clean

The hopper, pre-divider, and rounder can be extracted for easy cleaning.

This is the maximum capacity per hour of the 6-row version (stepless adjustment available). Up to 7500 pcs/hour with the 5-row version and 6000 pcs/hour with the 4-row version.

These rollers gently convey the dough to the chamber without stressing it, so less flour is needed.

You can adjust the pressure and amount of dough based on its texture. This innovative system doesn’t stress the dough, ensuring optimal processing.

It allows you to make a wide variety of buns of varying weight without having to replace any mechanical components, thus saving you time and money.

You can adjust the rounding space regardless of the dough piece’s weight. This option reduces the pressure on the dough, processing it without stressing it or compromising its volume.

Available in the Future version. It allows you to set all the machine parameters (e.g., weight, rounding chamber, rounding speed and time, flour duster).

You can even save all these settings as a recipe for future use.

The hopper, pre-divider, and rounder can be extracted for easy cleaning.

As gentle as a master baker

PRIMA Evo is a dough divider-rounder that mimics the accurate and gentle motion of a master baker. As a result, it can handle large amounts of various types of dough without stressing it. A special dosing system feeds the precise amount of dough to be divided and rounded for making round buns and rolls. A spring system compensates the piston’s pressure on the dough. This way, the machine can handle any dough (high or low-hydration) without stressing it. All these features are the product of 25 years of technical development and a journey that began back in 1887. PRIMA Evo is available in 4, 5, and 6-row versions with a weight range from 15 to 300 g. All this makes it an unrivalled ally in the bakery industry. Prima Evo can make a wide variety of products, whether you use it as a standalone machine or integrate it as a head machine into a complete line (available in various configurations).

Ease of use, excellent performance

PRIMA Evo makes the dough pieces you want in just a few simple steps. The hopper (with a weight capacity of 25 or 40 kg) feeds the dough through the infeed rollers and star cutting system to the chamber, where it’s cut into equal pieces of the desired weight. Then, the dough is divided by the pistons (set to the required weight) and rounded in the same chamber. This way, the dough is divided, rounded, and shaped into perfect balls in 3 easy steps. Felt pads oil the pistons with every drum turn to prevent the dough from sticking. Whatever dough you use – sticky, hard, or soft – you’ll always get excellent results. You can use the dials to adjust the pressure in the chamber and ensure a perfect result, whatever the weight range. Once rounded, the dough is either transferred to the outfeed belt to be manually collected or – if the machine is integrated into a complete line – to the following automated process. In addition, you can change the configurable parameters without stopping the machine.

Safe, practical, and hygienic

This machine is available in two versions, one controlled manually through handwheels and switches and the other electronically through a touchscreen, allowing you to save the programs as recipes for future use. PRIMA Evo is equipped with a standard safety device that automatically stops the drum when foreign objects (e.g. blades) get inside the machine, preventing severe damage.

In addition, it’s quick and easy to clean, thanks to its stainless steel surfaces and wide side doors. All its components are quick and easy to clean. The hopper, pre-divider, and rounder can be removed to clean every part of the machine in just a few minutes without regular maintenance.

Data Sheet

WEIGHT RANGE

Standard

15 – 55 g

20 – 70 g

30 – 85 g

35 – 90 g

40 – 100 g

45 – 110 g

50 – 120 g

60 – 140 g

70 – 160 g

75 – 170 g

Special versions

90 – 190 g

130 – 290 g

Double-piston system

20 – 140 g

30 – 160 g

15 – 120 g (mixed row version)

70 – 290 g (mixed row version)

Stepless adjustment.

Other weight ranges are available upon request.

The weight range depends on the dough’s texture and mixing process.

Voltage:

380 – 415 V / 50 or 60 Hz / 3 ph+N + PE

220 – 240 V

208 V

Power: 2.0 kW

Fuse: 16 A

CAPACITY

max 9000 pcs/hour with the 6-row version

max 7500 pcs/hour with the 5-row version

max 6000 pcs/hour with the 4-row versio

TYPES OF DOUGH

Soft, cold-rise, sticky, hard, and leavened dough:

Wheat dough

Mixed wheat dough

Rye dough

Bagel dough

Pretzel dough

Krapfen dough

Pastry dough

Special dough

PRODUCTS

A wide range of round, long, flat, scored rolls (e.g. Kaiser rolls), hot dog and burger buns, krapfens, pretzels, and more.

Discover all the other complete, automated bakery lines for buns and rolls as perfect as handmade ones.

Compact Line

Combi Line

Panning Line

Metra Line

Dividers & Rounders

Our dough divider-rounders are like no other because they process dough as gently and carefully as an artisan baker, ensuring excellent precision and high output. Prima Duo, Prima Trio, and Prima Evo meet the needs of all bakeries, from small artisan to large industrial ones.

Prima Duo

Prima Trio

Prima Evo