Metra Line

Metra Line is the complete line for making bread of any shape and size. It uses a Metra checkweigher-divider as a head machine, allowing it to process any dough – wheat, rye, mixed, soft, and hard – without stressing it, always ensuring excellent quality. This fully automatic line can be operated by one person. In addition, it allows you to define the characteristics of the desired final product. In its complete configuration, the Metra Line consists of a feeding hopper, a conical divider-rounder, a moulding station, and a proofing cabinet.

Type of Bun

Every process – from when the dough is fed to the hopper to when it’s divided and placed on the conveyor belts – is automated and can be controlled from the touchscreen. You can save the various settings as a recipe for future use. Other functions include stepless weight adjustment, digital piece counter (with pre-setting function), machine cleaning and standard position.

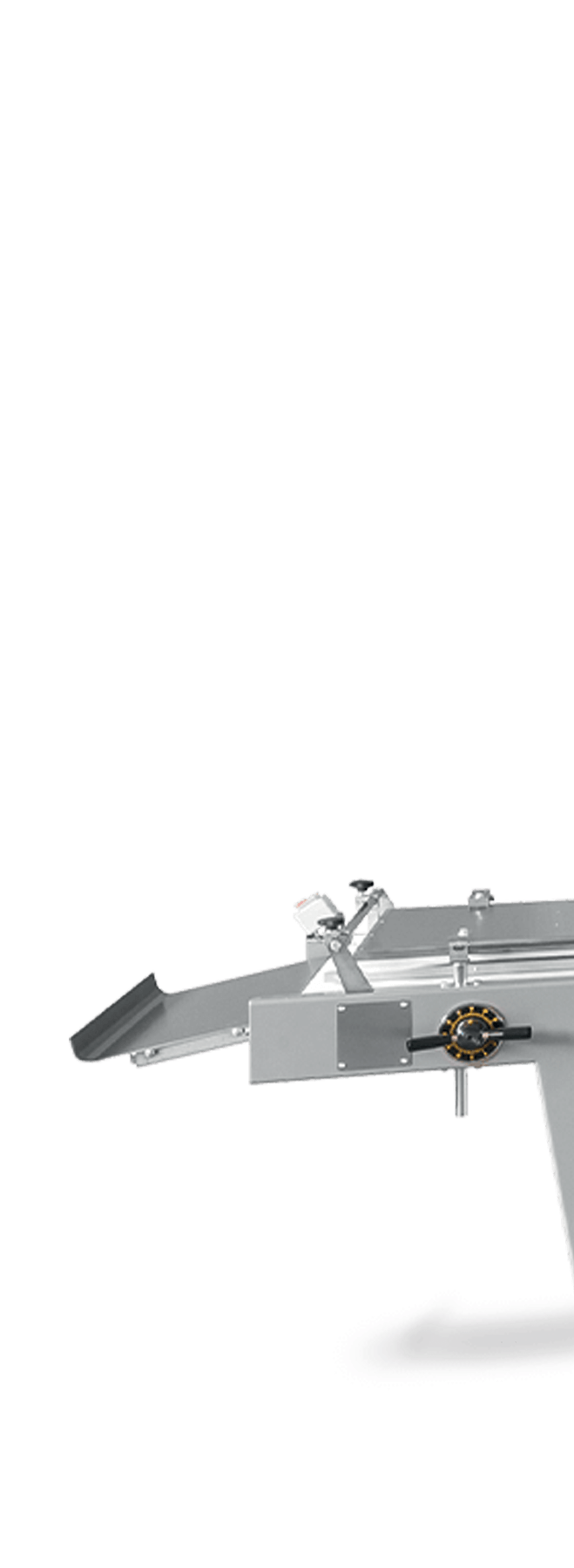

Moulding station

This solid unit complies with all the latest European standards. It creates long-rolled bread using only wheat or mixed flour (wheat and rye). The dough fed to the machine through the hopper passes through a set of rollers, which give it the desired thickness. Then it’s conveyed to the pressure board, where it’s long-rolled.You can easily adjust the pressure board’s height through two manual controls. The machine is also equipped with adjustable side guides.

Proofing cabinet

This intermediate proofing cabinet is for dough pieces weighing up to 1.2 kg with a 4 to 20-minute resting time. A UV lamp prevents bacterial proliferation.

Conical rounder

Ideal for rounding soft and medium dough. A rotating cone pushes the dough along concave spirals, giving it a spherical shape. The spirals are Teflon-coated to prevent the dough from sticking to them. This machine has a standard automatic flour duster, which you can easily remove for cleaning. In addition, it can be fitted with a hot/cold air blower to process moist dough.

Feeding hopper

This unit allows you to feed the dough divider with even pieces of dough, optimising its operation. You can quickly remove its internal components for easy cleaning.

Dough divider

An extending piston pushes the dough from the hopper to its designated space. Then, the checkweigher closes the space, and the piston pushes the dough into the measurement chamber.

The measurement chamber’s volume is that of the pre-set dough weight and dictates the amount of dough drawn in. This method prevents the dough from returning to the hopper. Finally, the dough pieces are released onto the outfeed belt.

Discover all the other complete, automated bakery lines for buns and rolls as perfect as handmade ones.

Dividers & Rounders

Our dough divider-rounders are like no other because they process dough as gently and carefully as an artisan baker, ensuring excellent precision and high output. Prima Duo, Prima Trio, and Prima Evo meet the needs of all bakeries, from small artisan to large industrial ones.

Prima Duo

Prima Trio

Prima Evo