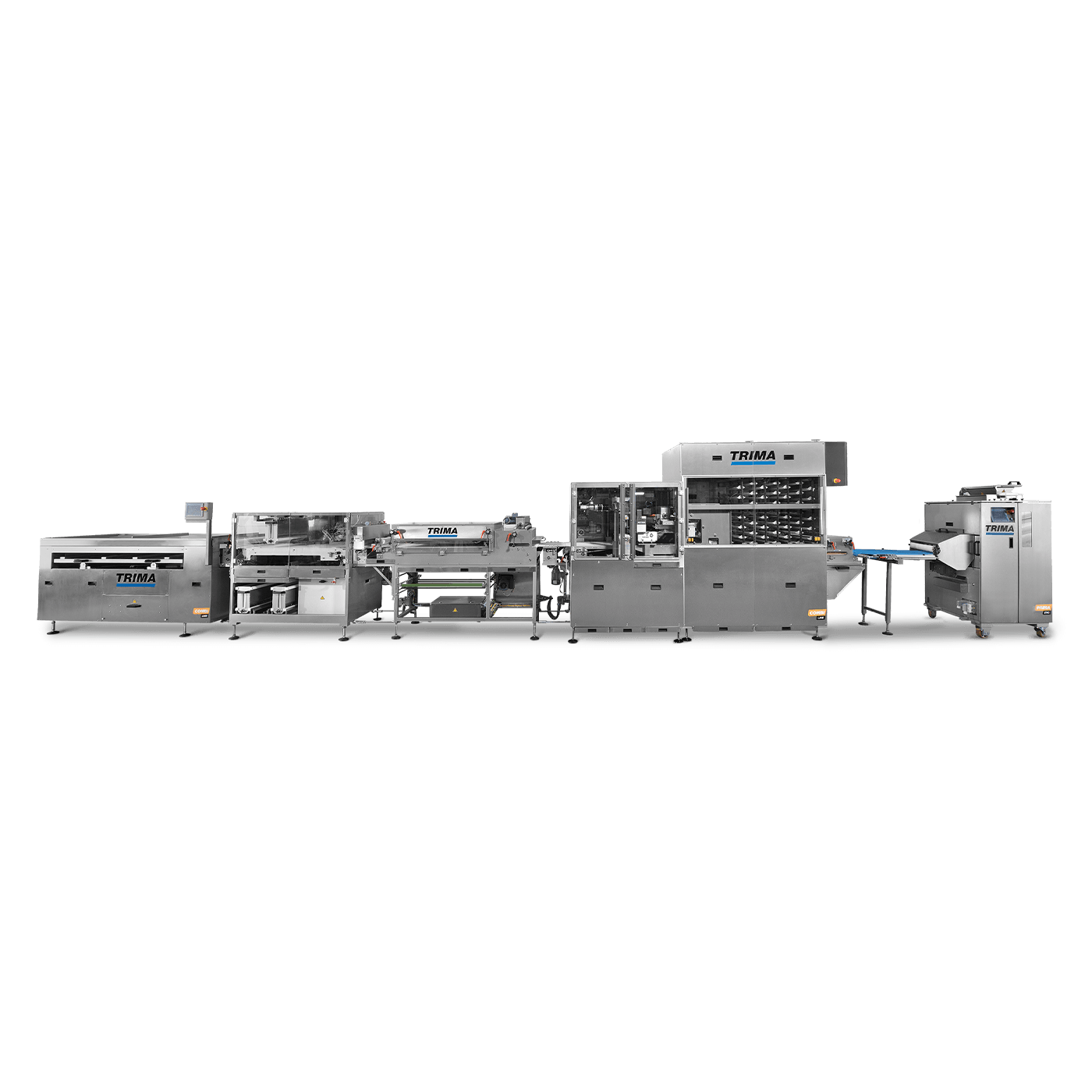

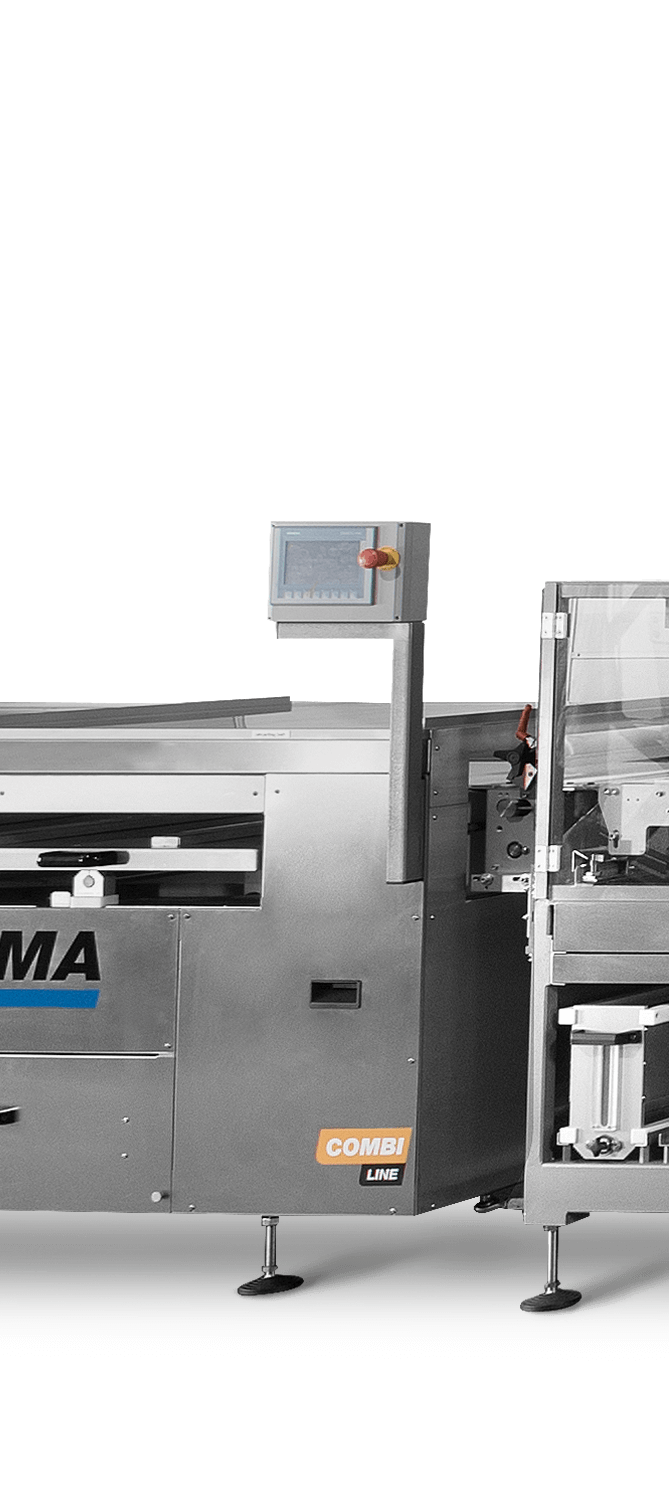

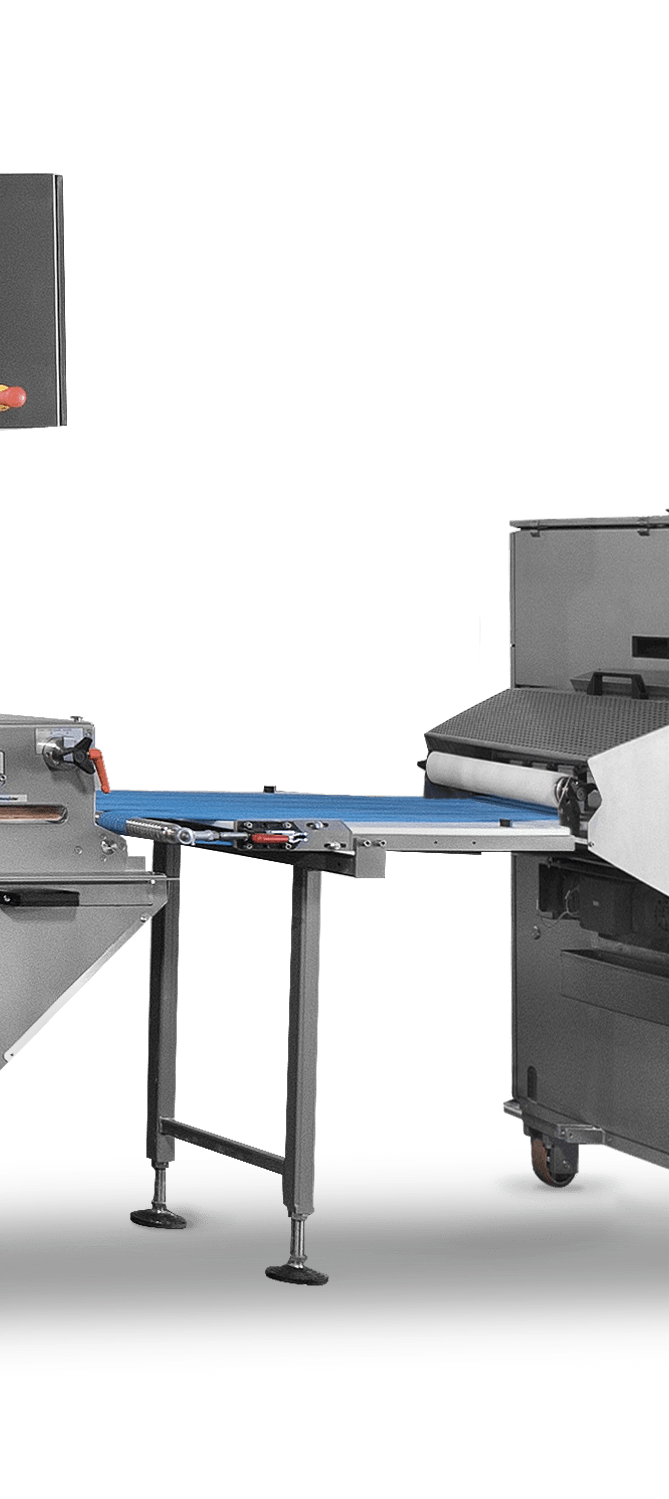

Combi Line

Trima’s Combi Line provides every bakery business with a complete modular line tailored to their production and space requirements. Combi Line makes artisan-quality buns and rolls of any shape and size, allowing you to automatically manage every stage of the process – from dough dividing to panning.

Type of Bun

Combi Line: the flexible modular roll production line tailored to your needs.

Panning station

A universal, fully automatic panning station where the freshly moulded dough is accurately placed in proofing or baking trays. Its control system allows you to set the pitch between the dough pieces (even using intermediate values). The panning station is available in various lengths according to the number and size of the trays.

Seeding station

This is where the dough pieces are sprayed with water and seeded. You can easily remove it from the line to make it easier to clean. This unit has various containers with various seeds, grains (coarse to fine), and toppings (e.g. poppy, sesame, pumpkin seeds and flour). You can insert the containers manually and adjust the amount to be sprinkled. Excess seeds are collected in a container and reused. The mesh belt, including the storage rack, can be removed from the unit for cleaning (the stainless steel version can be cleaned with a high-pressure cleaner). The double topping option is available upon request.

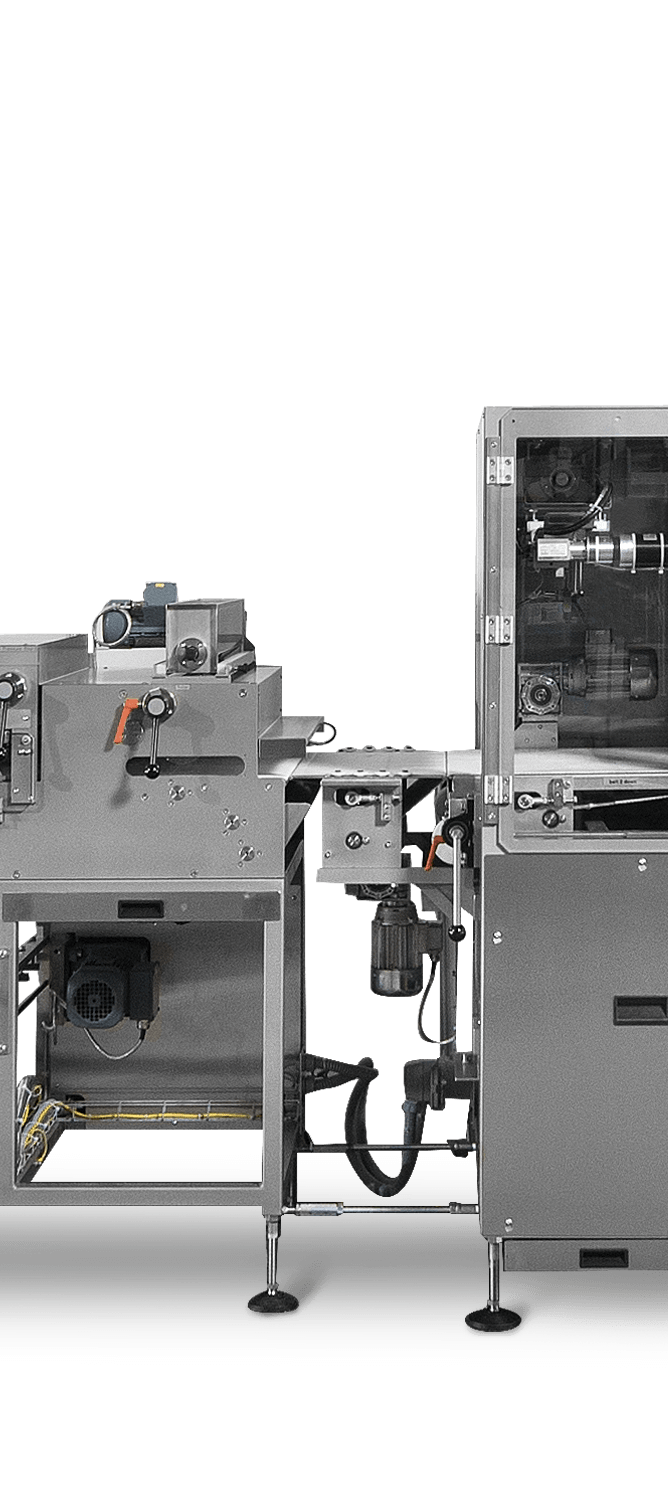

Moulding station

This unit produces flat or long rolls like mini baguettes, hot dog rolls, and burger buns. The pressure /long-rolling board processes the dough without stressing it, ensuring excellent evenness and quality.

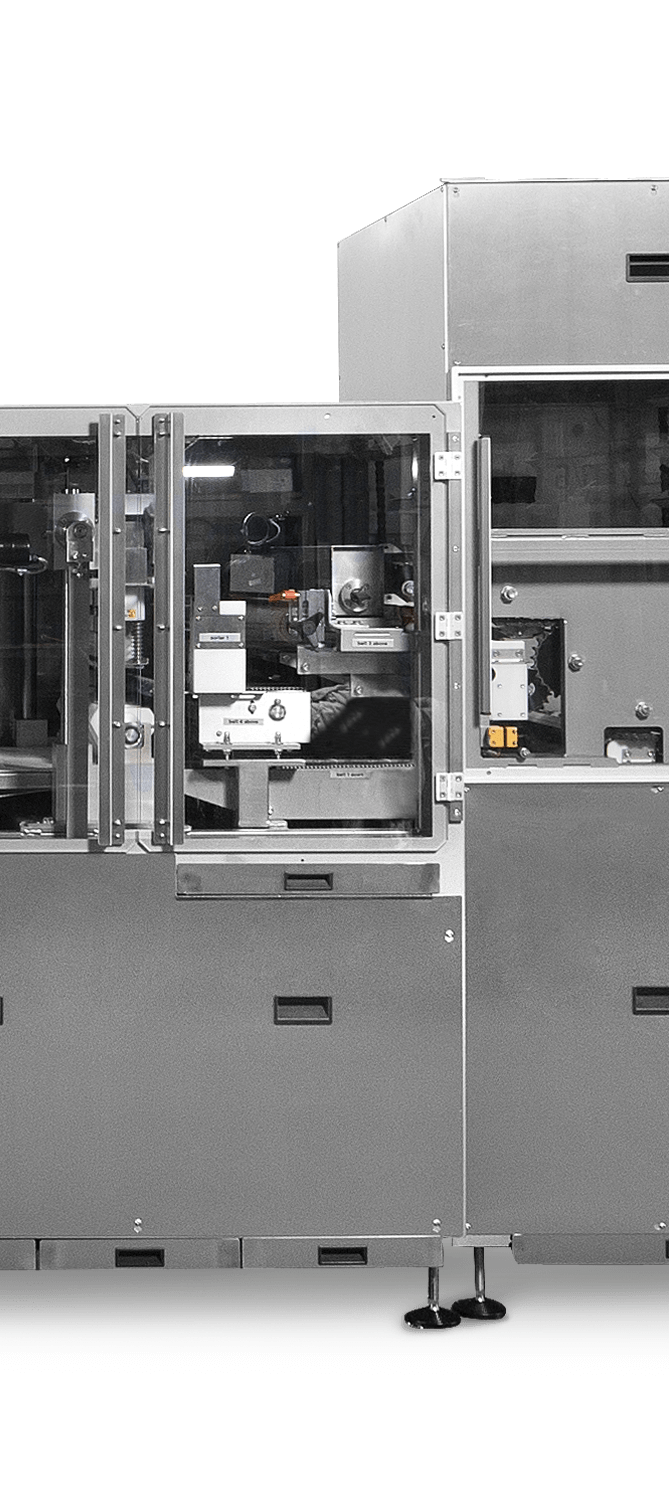

Stamping station

Based on the product, the dough is placed in round or long cups, where they are stamped or scored.

The stamping station is equipped with a rotating stamping tool for Kaiser rolls and a pressing tool for other patterned buns and rolls. The stamping head can be easily swivelled out to bring the stamping tools to their working position. Moreover, you can quickly change the stamping tools whenever you need to make another product. Finally, the stamping cups are deep and made of food-grade plastic, ensuring higher quality.

Proofing cabinet

The proofing cabinet has stainless steel swing trays with cotton liners. The swing trays are UV-sterilised and dried by a fan when they return to their starting position. A climate control system (temperature and humidity) is available upon request. The proofing cabinet is available in various sizes based on resting time. It can also be fitted with a bypass conveyor upon request to bring round products that don’t require proofing directly to the panning station.

Pre-rolling unit

This unit is positioned before the proofing cabinet and makes oval dough pieces. This is the first stage of making long-rolled bread and patterned oval rolls.

Divider-rounder

The Combi Line bakery line uses a Prima Evo dough divider-rounder as a head machine, the ideal solution for gently processing dough without stressing it. Head machines with up to six rows are available. These machines allow you to handle large amounts of various types of dough without stressing it, always ensuring excellent weight accuracy. The weight range is from 20 to 150 g.

Number of rows

Select the number of pockets to place the exact number of dough pieces on the trays. The filling piston is also easy to replace without any tools.

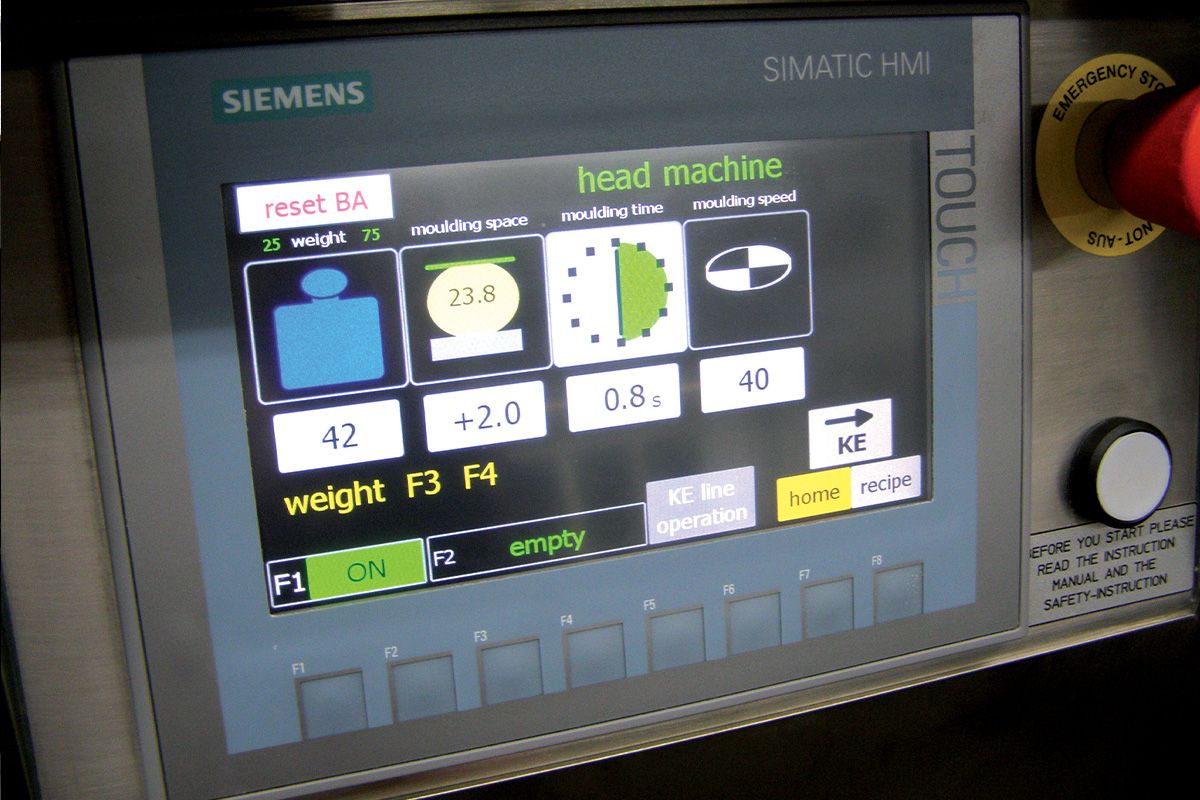

PLC control

The machine is controlled via a Siemens S7 PLC with a touchscreen panel. Based on the required program, the unit will switch to the selected product (partly automatically and partly by controlling the menu). You can set all the machine parameters and save them for future use.

At the beginning of each line stands Prima Evo

9000 pieces

This is the maximum capacity per hour of the 6-row version (stepless adjustment available). Up to 7500 pcs/hour with the 5-row version and 6000 pcs/hour with the 4-row version.

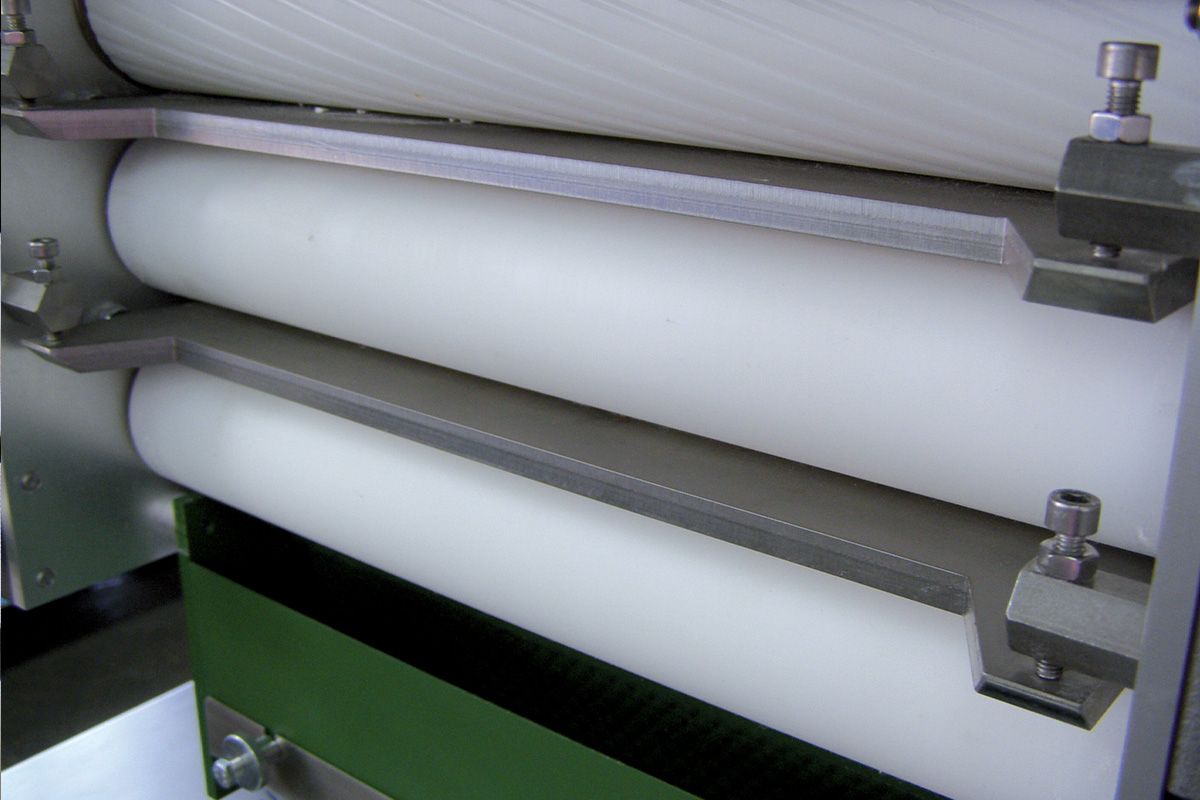

Infeed rollers

These rollers gently convey the dough to the chamber without stressing it, so less flour is needed.

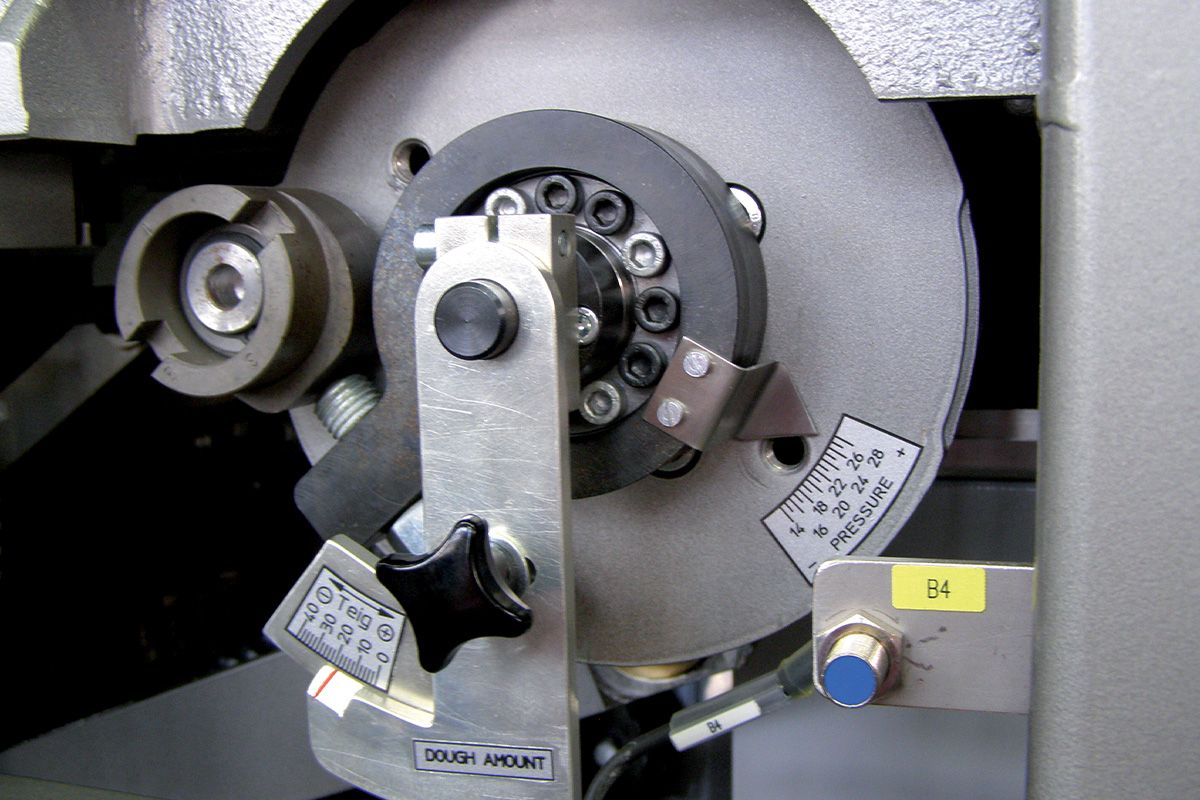

Adjustable pressure

You can adjust the pressure and amount of dough based on its texture. This innovative system doesn’t stress the dough, ensuring optimal processing.

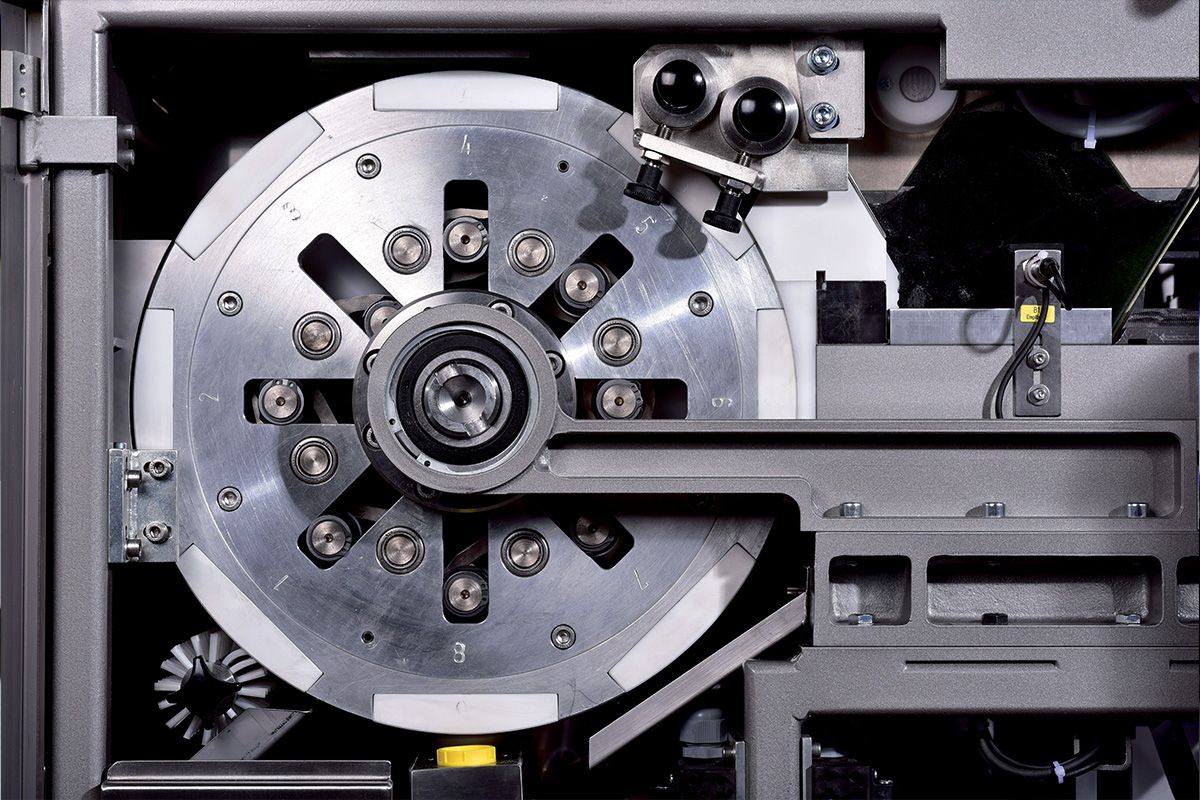

Double-piston drum

It allows you to make a wide variety of buns of varying weight without having to replace any mechanical components, thus saving you time and money.

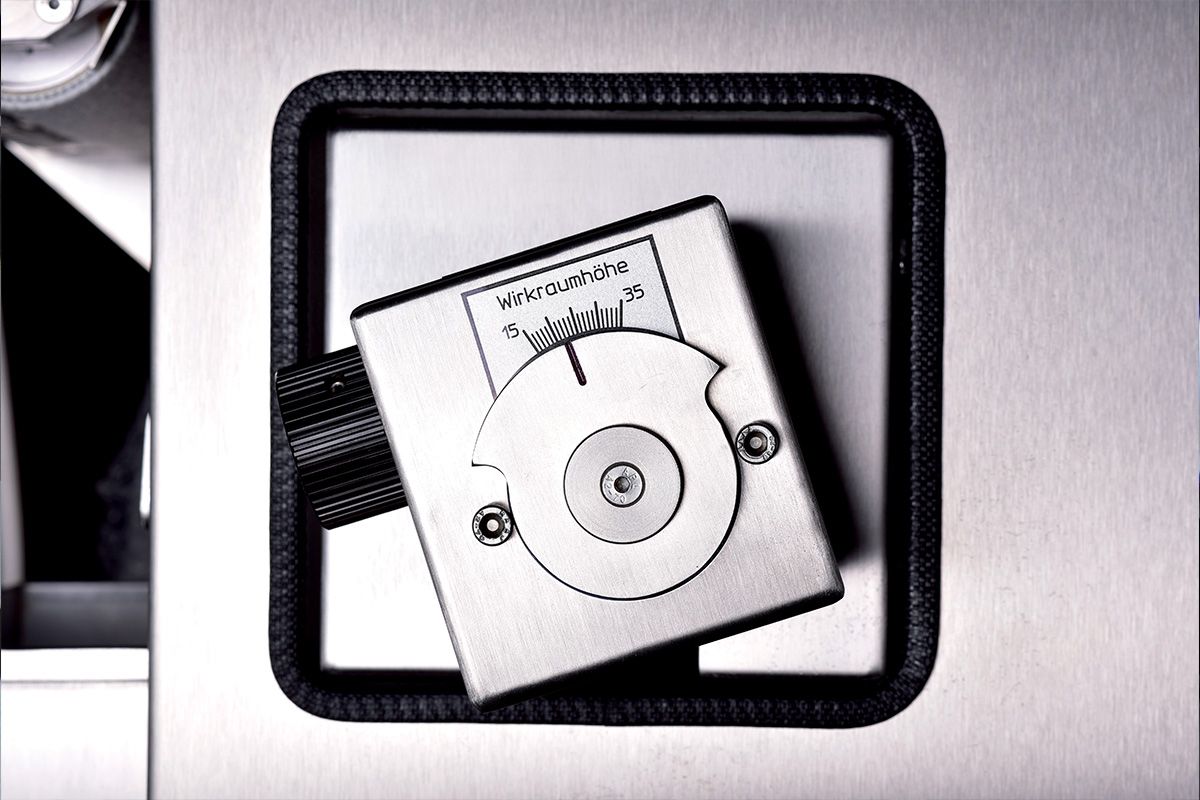

Separate rounding chamber adjustment

You can adjust the rounding space regardless of the dough piece’s weight. This option reduces the pressure on the dough, processing it without stressing it or compromising its volume.

Interactive touch screen

Available in the Future version. It allows you to set all the machine parameters (e.g., weight, rounding chamber, rounding speed and time, flour duster).

You can even save all these settings as a recipe for future use.

Easy to clean

The hopper, pre-divider, and rounder can be extracted for easy cleaning.

This is the maximum capacity per hour of the 6-row version (stepless adjustment available). Up to 7500 pcs/hour with the 5-row version and 6000 pcs/hour with the 4-row version.

These rollers gently convey the dough to the chamber without stressing it, so less flour is needed.

You can adjust the pressure and amount of dough based on its texture. This innovative system doesn’t stress the dough, ensuring optimal processing.

It allows you to make a wide variety of buns of varying weight without having to replace any mechanical components, thus saving you time and money.

You can adjust the rounding space regardless of the dough piece’s weight. This option reduces the pressure on the dough, processing it without stressing it or compromising its volume.

Available in the Future version. It allows you to set all the machine parameters (e.g., weight, rounding chamber, rounding speed and time, flour duster).

You can even save all these settings as a recipe for future use.

The hopper, pre-divider, and rounder can be extracted for easy cleaning.

Discover all the other complete, automated bakery lines for buns and rolls as perfect as handmade ones.

Dividers & Rounders

Our dough divider-rounders are like no other because they process dough as gently and carefully as an artisan baker, ensuring excellent precision and high output. Prima Duo, Prima Trio, and Prima Evo meet the needs of all bakeries, from small artisan to large industrial ones.

Prima Duo

Prima Trio

Prima Evo