Metra

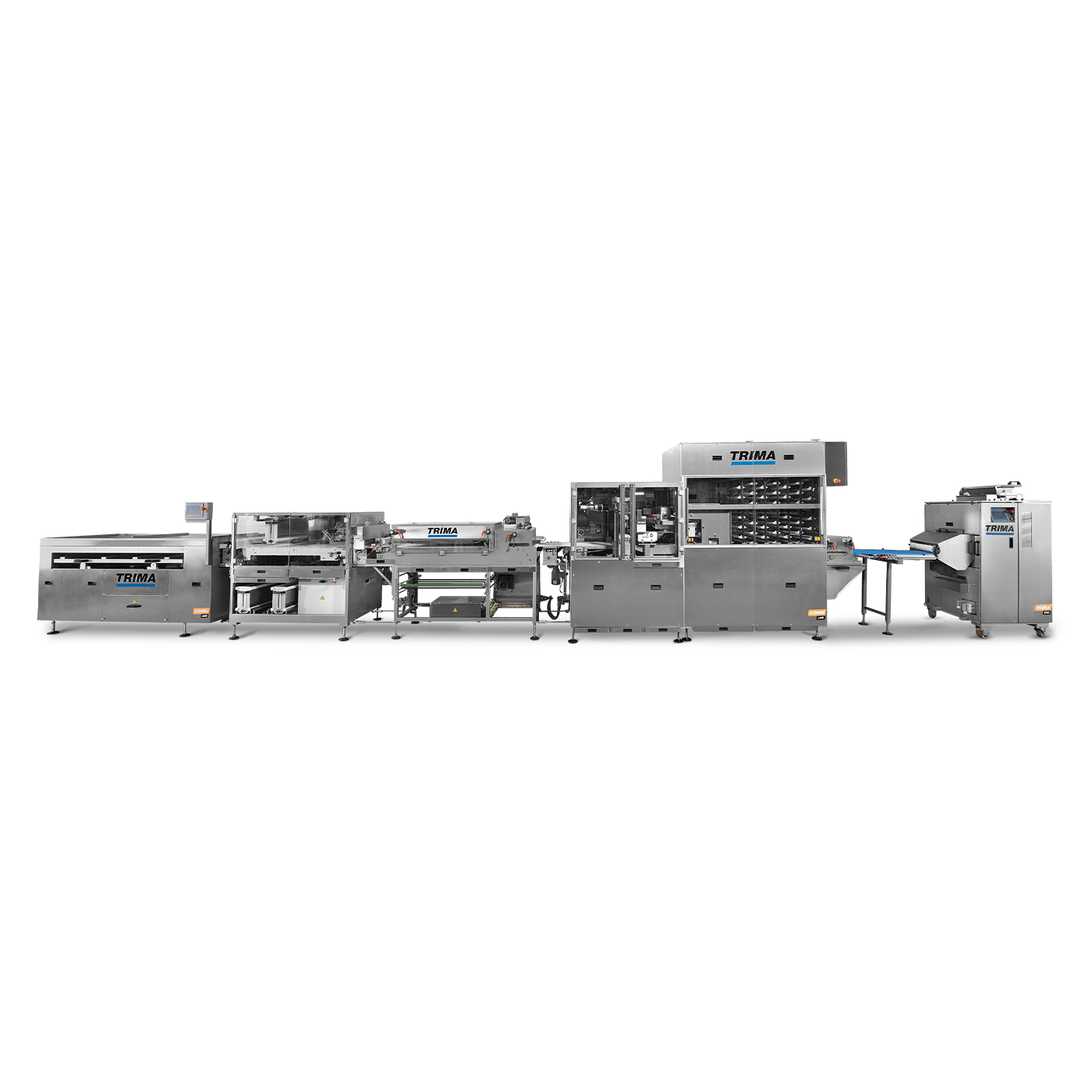

Metra is a dough checkweigher-divider that makes artisan-quality bread. With this machine, medium and large bakery businesses no longer have to choose between productivity and quality. Its perfectly designed internal mechanisms allow it to gently process large amounts of dough, producing identical portions of the desired weight and size. Metra can be used as a standalone machine or integrated as a head machine into a complete line for making bread of any shape and size.

Weight Range

250 – 2700 g (single-piston version)

Capacity

Up to 3000 pcs/hour (2-piston version)

Up to 1500 pcs/hour (single-piston version)

Stepless speed control.

Master bakers’ expertise is the inspiration behind this state-of-the-art dough divider that gently processes dough, ensuring excellent weighing precision.

Plus

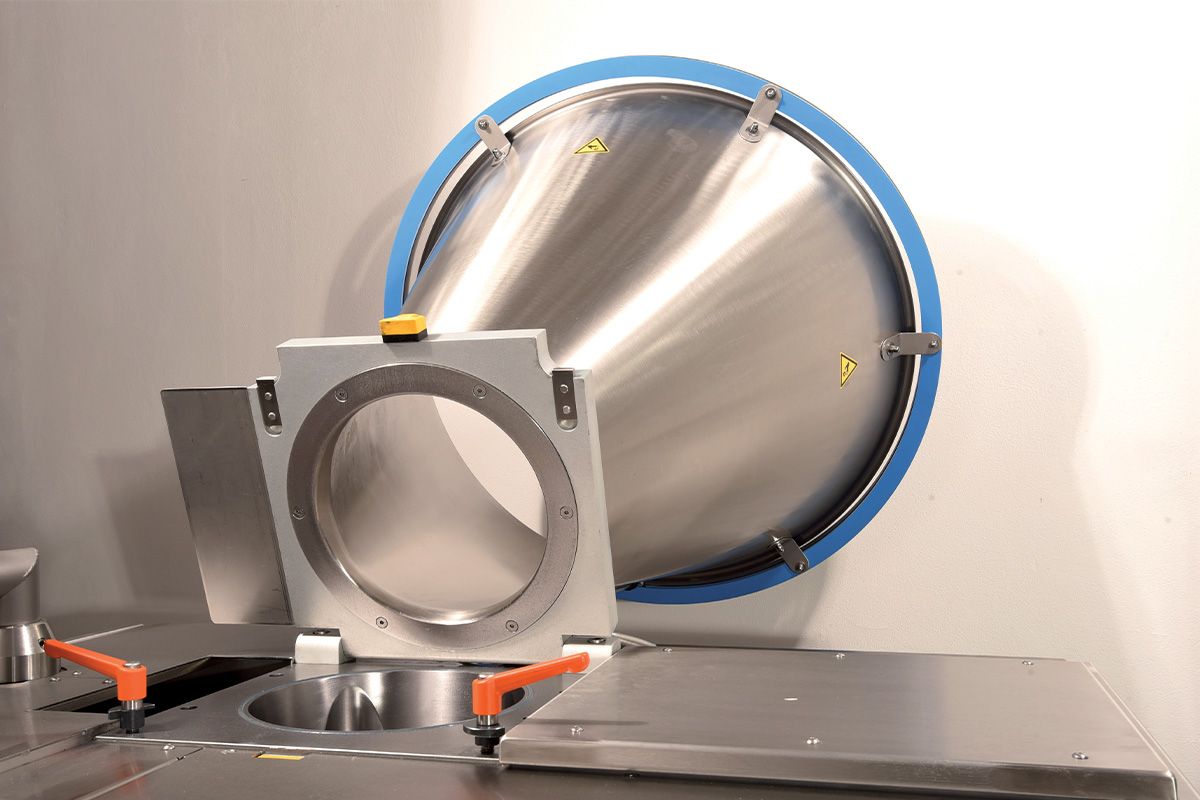

Feeding hopper

The standard weight capacity is 120 kg; however, a 200 kg version is also available. The hopper goes all the way down to the knife, so no dough is left behind. In addition, it’s equipped with sophisticated safety devices that stop the machine automatically as soon as the hopper’s safety edge is touched.

Automatic lubrication system

The knife and piston lubrication system can be adjusted according to needs to minimise oil consumption.

Interactive touchscreen

The interactive touchscreen with a swivel arm allows you to set all the machine parameters (e.g., weight, speed, piece counter with pre-setting option and auto stop). You can save the settings as a recipe for future use.

Easy-to-clean hopper

You can tilt the hopper left or right for easy cleaning.

Easy shifting between single to double-piston operation

This dough divider can operate with 1 or 2 pistons, and you can quickly shift between single and double-piston operation to make a wide range of products with different weights.

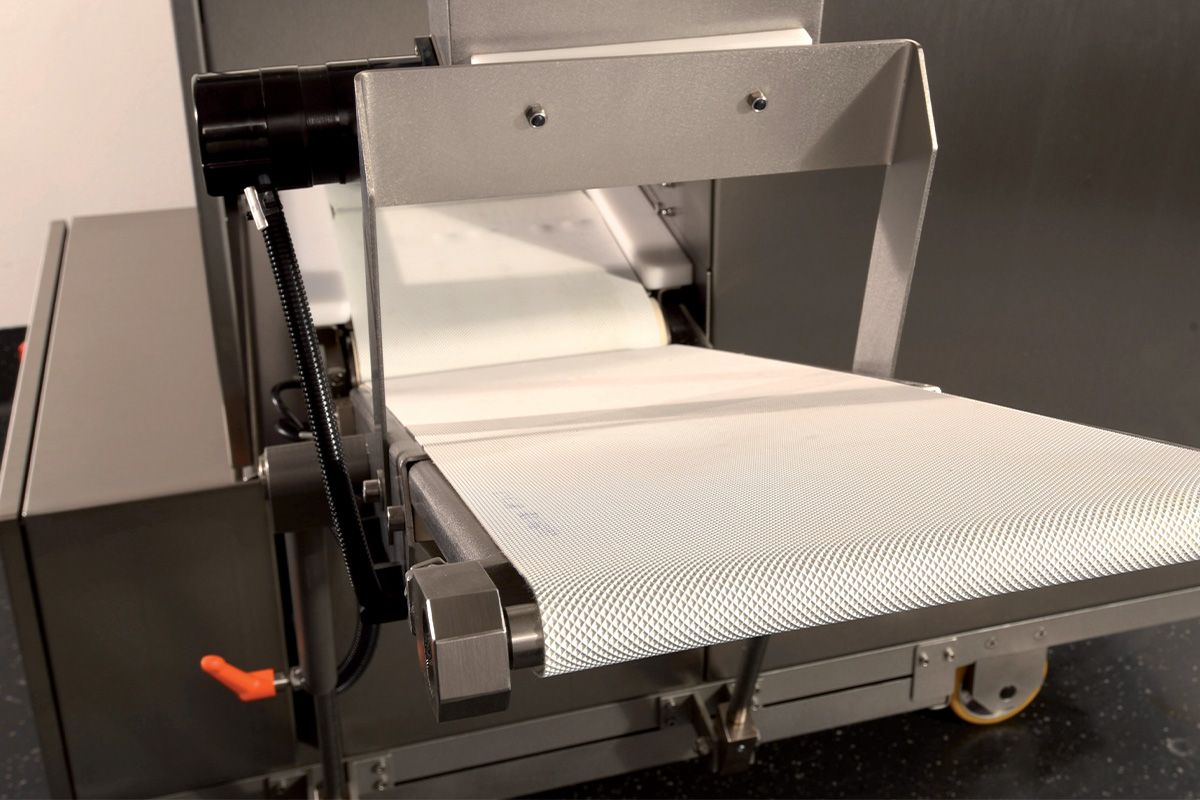

Outfeed belt

The belt can be of various lengths. You can adjust its height and choose its direction (left or right).

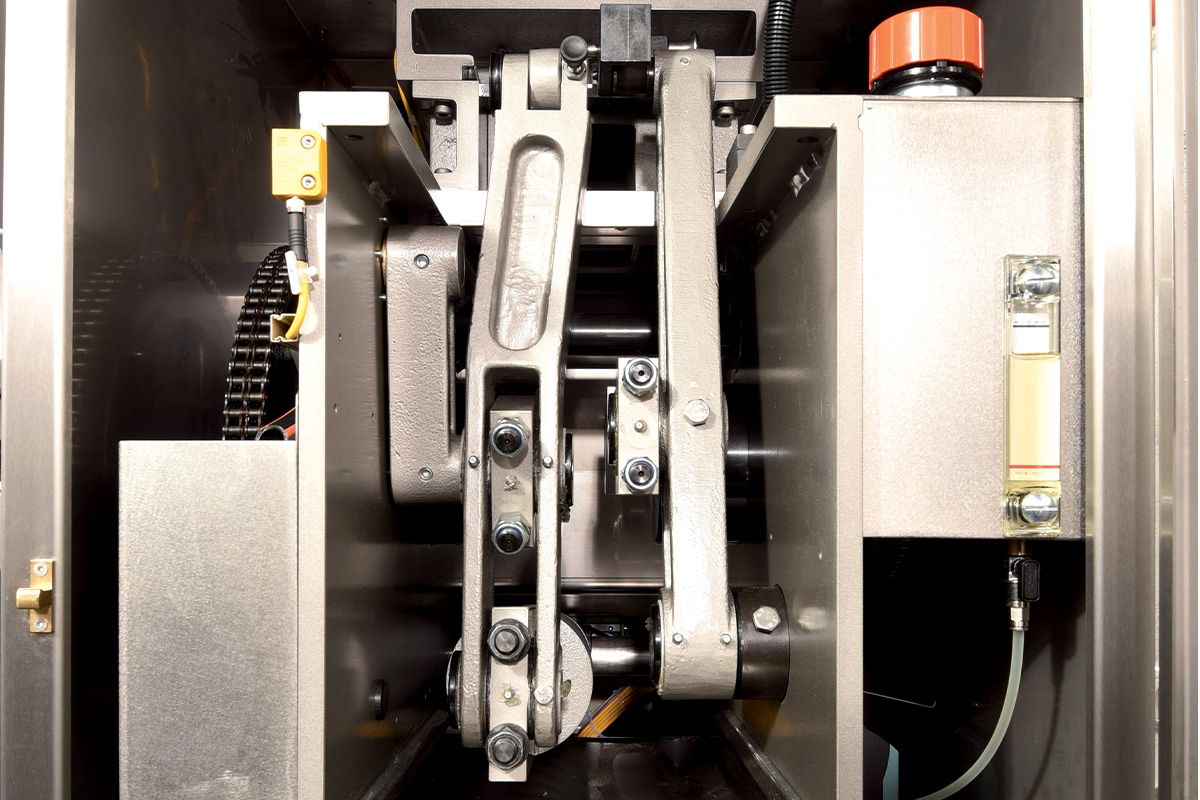

Two-step division

An adjustable vacuum system draws the dough into the chamber. Then, once the knife is closed, the pistons are filled. The dough is gently divided thanks to a dough pusher and dividing pistons. In addition, the Ni-Resist steel chamber is durable and ensures excellent weight accuracy.

Reliable mechanisms

This sturdy machine is perfect for medium to large industrial bakeries.

The standard weight capacity is 120 kg; however, a 200 kg version is also available. The hopper goes all the way down to the knife, so no dough is left behind. In addition, it’s equipped with sophisticated safety devices that stop the machine automatically as soon as the hopper’s safety edge is touched.

The knife and piston lubrication system can be adjusted according to needs to minimise oil consumption.

The interactive touchscreen with a swivel arm allows you to set all the machine parameters (e.g., weight, speed, piece counter with pre-setting option and auto stop). You can save the settings as a recipe for future use.

You can tilt the hopper left or right for easy cleaning.

This dough divider can operate with 1 or 2 pistons, and you can quickly shift between single and double-piston operation to make a wide range of products with different weights.

The belt can be of various lengths. You can adjust its height and choose its direction (left or right).

This sturdy machine is perfect for medium to large industrial bakeries.

A sturdy yet gentle dough divider for artisan-quality bread

Metra is a compact, versatile, and cost-effective dough divider.

It produces excellent results in just a few simple steps, every one of which – from infeed to outfeed – is fully automated. In addition, it accurately weighs even the tiniest batch of dough. All the dough is discharged from the machine, so you can effortlessly process other types of dough without having to worry about cleaning it first. Metra has a 2-step division system. First, the dough is drawn into the chamber through a vacuum system (the vacuum level depends on the weight). Then, once the knife is closed, the pistons are filled. This way, you can process any dough (e.g., high or low-hydration, delicate, and leavened dough) without stressing it. All these features are the product of 25 years of technical development and a journey that began back in 1887. Metra is an ally like no other for your bakery business. You can use it as a standalone machine or integrate it as a head machine into a Metra Line system (in any of its various configurations).

Volumetric division and accurate scaling

Based on the weight range, this machine can work with 1 or 2 rows. Accurate scaling allows it to handle the dough gently. Here’s how it works: first, the extending piston conveys the dough from the hopper to its designated space. When the knife is entirely open, the vacuum system draws in the previously set amount of dough. Then, the blade closes the dough space, and the piston pushes the dough into the measurement chamber. When the knife is closed, the filling process can begin. The measurement chamber’s volume is that of the pre-set dough weight and dictates the amount of dough drawn in. This method prevents compression and the dough from returning to the hopper. It also ensures gentle dough handling without stressing it. Finally, the dough pieces are released to the outfeed belt, where they are manually collected or – if the machine is integrated into a complete line – transferred to the following automated process. The speed of the two outfeed belts can be set independently from one another.

Practical and hygienic

All the machine settings are managed from the touchscreen and can be saved as recipes in the relevant section. This way, all variable parameters will adapt to the selected recipe. This additional feature helps reduce conversion time. In addition, you can easily change the set values in a stored recipe. Other Metra functions include stepless weight adjustment, digital piece counter (with pre-setting function), machine cleaning and standard position.

The touchscreen also displays operating and alert messages.

You can even change parameters during the process without stopping the machine. Metra’s stainless steel surfaces and wide doors facilitate maintenance and make the whole machine quick and easy to clean.

In addition, Metra is on wheels, making it easy to move and ensuring enough ground clearance.

Data Sheet

WEIGHT RANGE

125 – 1200 g (2-piston version)

250 – 2700 g (single-piston version)

Stepless speed control.

The weight range depends on the dough’s texture and mixing process.

Voltage:

380 – 415 V / 50 or 60 Hz / 3ph+N + PE

220 – 240 V

208 V

Power: 2.0 kW

Fuse: 16 A

CAPACITY

Up to 3000 pcs/hour (2-piston version)

Up to 1500 pcs/hour (single-piston version)

Stepless speed control.

OPTIONS

Hopper lubrication system

Steep conveyor belt

Extended outfeed belt

TTeflon-coated hopper

Flour duster (instead of belt lubrication)

TYPES OF DOUGH

Suitable for soft, hard, sticky, and cold-rise dough, including:

Wheat dough

Rye dough

Mixed dough

Pastry dough

Special dough

PRODUCTS

A wide range of excellent bread, baguettes, tin bread, and more.

Discover all the other complete, automated bakery lines for buns and rolls as perfect as handmade ones.

Compact Line

Combi Line

Panning Line

Metra Line

Dividers & Rounders

Our dough divider-rounders are like no other because they process dough as gently and carefully as an artisan baker, ensuring excellent precision and high output. Prima Duo, Prima Trio, and Prima Evo meet the needs of all bakeries, from small artisan to large industrial ones.

Prima Duo

Prima Trio

Prima Evo